From the West Hartford Archives: Reservoir Filtration Plant and Aerator

Audio By Carbonatix

Photo courtesy of Noah Webster House & West Hartford Historical Society

Historian Jeff Murray takes a look into West Hartford’s past to uncover some surprising information, stir up some memories, or reflect on how much life has changed – or hasn’t changed at all. Enjoy this week’s ‘From West Hartford’s Archives’ …

By Jeff Murray

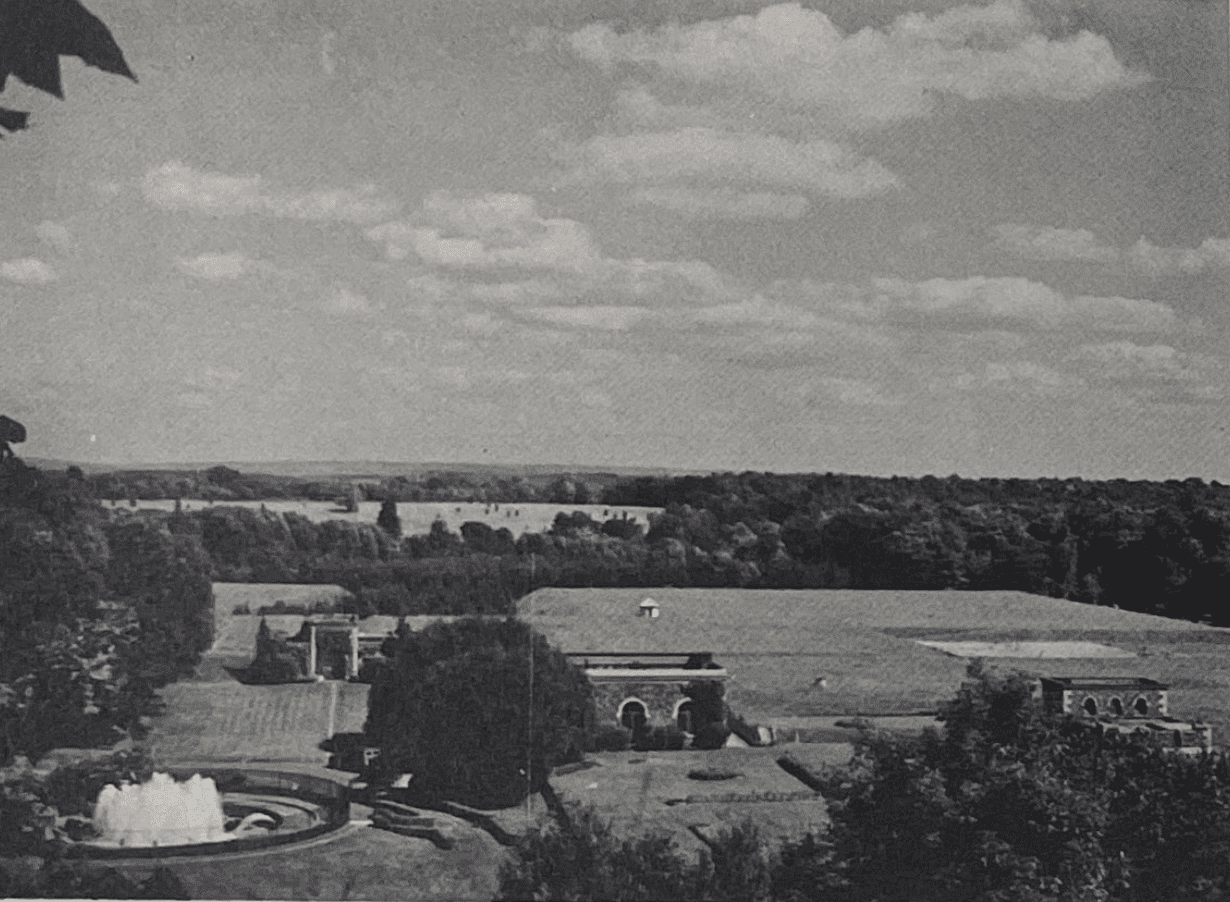

This photo of the Reservoir filtration plant and aerator fountain was taken around 1955 as part of a commemorative book celebrating the centennial of the public water supply to Hartford.

On Oct. 23, 1855, the Water Board of the City of Hartford tested a new engine that would pump water from the Connecticut River to the Lord’s Hill Reservoir on Garden Street. Hartford was industrializing rapidly and had more than tripled in population from 1830 to 1855, with factories, foundries, and housing that created new, urgent demands for clean water. River water was used by more wealthier families closer to the source while well water was hard and sulfuric.

By the late 1840s, the demand for a public water system grew: epidemics like cholera and typhoid showed the connection to health and political advocates tied a more modern water infrastructure to the idea of prosperity. Other cities like New York and Boston had built large-scale pumping and aqueduct systems in the same decade. After years of political stagnation, the Hartford councilmen adopted a plan to deliver water to a new reservoir on Lord’s Hill in Hartford using this new pump.

There were hiccups in the early years, mainly financial and some political. The main problem though was supply. The reservoir was simply too small to meet future growth, especially with wasted water. In the winter months, water users left faucets running to prevent pipes from freezing. Rather than change daily habits, the Board recommended in 1860 that a reservoir be built in West Hartford to supply water to the city by gravity. Since water flows downward naturally under pressure created by its own weight, the city could simply build on land above the elevation of the city and provide a flow strong enough to supply the city’s needs.

Reports on the use of Trout Brook for quality and supply were favorable. The Board purchased 80 acres of land off Farmington Avenue in 1864 and after a few years of legal injunctions and political bickering, Reservoir #1 was built. It began to supply water by gravity to Hartford starting on Jan. 2, 1867.

Less than a year later, a storm hit West Hartford and collapsed the dam at Reservoir #2, which was under construction. The waters flowed down into Reservoir #1 and flooded the surrounding area. Over the next two decades, the other reservoirs were built, with Reservoir #1 serving as the distributing reservoir. Different conditions and historical needs prompted each reservoir’s construction from the 1870s to the 1880s, with Reservoir #6 completed in 1895 along the canal that connected it to the other bodies through Albany Avenue.

Of course, the next three decades saw immense growth in both the greater Hartford area and its population, meaning new land was needed for more water! The board looked to Canton, Burlington, and New Hartford, specifically the Nepaug River. The mission was simple: supply Hartford with an endless supply of water. In the early 1910s, the project went ahead to build a reservoir at Barkhamsted and Nepaug and connect new storage reservoirs with the West Hartford reservoir. Alongside this project was the proposal to build a filtration plant in West Hartford to treat all the water passing from the reservoirs.

The subject of a filtration plant had come up before, but it hadn’t materialized. The Hartford Courant wrote in 1908: “It is impossible to persuade the average man to boil the water before drinking it … The water is there, flowing right out of the faucet, and it looks all right … As things stand today, this means that the city will experience a siege of typhoid fever.” Of course, this was referring to the Connecticut River water, but the sentiment remained the same: unfiltered water was a public health risk. “A single case of walking typhoid in a passing tramp may tomorrow plant germs in our West Hartford system. Every drop that we drink should be filtered. This is fundamental.”

By 1913, the water system relied on a series of brooks flowing off Talcott Mountain into the reservoirs. Contractors working on the Nepaug project, connecting the water supply to the northwest of Talcott Mountain, lived near the construction area in West Hartford, which risked human waste and runoff contaminating the water. The city therefore built a small chlorination station directly on one of the larger brooks entering the reservoir system (Hawley Brook) to sterilize the water. The chief engineer of the project, Caleb Mills Saville, insisted on building this hypochlorite plant as a precaution, testing the incoming stream water for contamination and testing the treated water. Reservoir #1 had its own hypochlorite plant built. Chlorine treatment was quite new, but proven and many cities were installing these types of plants in the years leading up to World War I.

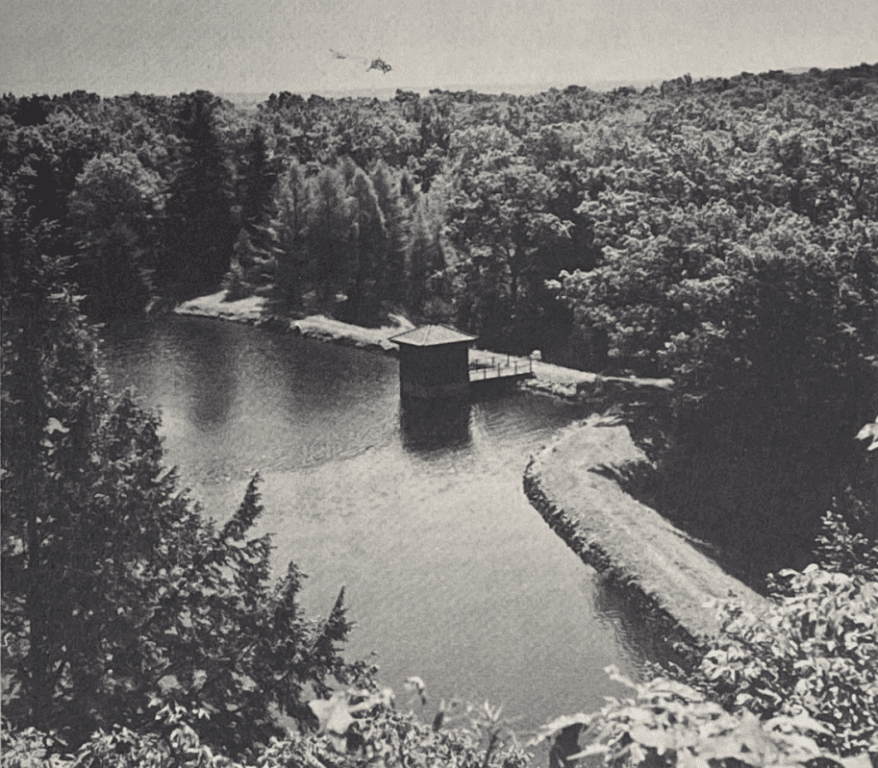

Reservoir #5 in the 1950s. Photo courtesy of Noah Webster House & West Hartford Historical Society

During World War I, work on the project was slowed down, but planning and preparation continued. The West Hartford water remained relatively untreated at high volumes and “during certain periods, it has offended the eye by its brown or red color and at other times its taste has been distinctly fishy and disagreeable.” It was apparently considered excellent quality; this was not good enough though and the idea of a filtration plant remained in the minds of the engineers.

It also was discussed by doctors, who differed in opinion. Some believed that the water supply should be treated by chemicals, while others believed it would be better to adopt the slow sand filtration that wouldn’t rely on chemical treatment. Test facilities were built in 1915 into 1916 to begin experimenting.

When Fern Street was being ripped up in 1917 for the giant water main that would supply Hartford with the new water connections from Nepaug, the newspaper said it looked like a warzone. They did not mince words either, describing the scene as looking “a great deal like the graveyard of Rheims Cathedral after the Germans got through with it.”

In 1919, work began on the new filtration plant between Reservoir #1 and #5 after the Nepaug water system was connected with West Hartford under Talcott Mountain. Contractors had to spend a significant amount of time just clearing thick brush and trees on the site.

Rather than overt chemical treatment, the West Hartford filtration plant would physically filter the new water supply to remove sediment, color, and bacteria. When piped into the reservoir system, the first stop would be the aeration chamber (a circular fountain), where water would be splashed into the air. This simple process would absorb oxygen from the atmosphere, remove odorous dissolved gases (like hydrogen sulfide), react with metals in the water which would be removed by later filtration, and give the water a “fresh” quality by moving it around. This aerator can be seen on display in the 1955 featured photo in the bottom left.

After aeration, the water would flow very slowly through sand filter beds. These large rectangular basins made of concrete would be layered with gravel at the bottom and finer sand to trap particulates. The plant would consist of eight separate beds arranged in two rows of four across six acres, allowing for continuous operation during maintenance. As the water percolates down through the sand, impurities would be physically strained out and broken down. Surplus water would be piped into a storage basin.

Excavation by large, coal-powered mechanical steam shovels had to be precise to ensure that the filter beds were perfectly level for even water flow through the sand. A temporary rail track was connected to the Farmington Avenue trolley line that passed through to Unionville so that sand, gravel, cement, and steel could be delivered directly by railcar. In addition, the engineers built a woodworking plant on the site. The filter beds were made of reinforced concrete, but before pouring, they needed wooden molds to shape the basins. A power station was constructed too to supply compressed air for the pneumatic drillers and mechanical energy for the concrete mixers. For two years, this became a self-sufficient industrial camp.

The storage basin was of reinforced concrete and was the final stage before the purified water entered the city’s distribution mains. Engineers had to contend with another problem. In a large holding basin, still water can grow algae, lose oxygen, and stagnate. How do you keep the water flowing without … flowing it all to the distribution pipes? The engineers built internal walls and baffles that guided the water to flow in an S-shaped path through the basin, ensuring continuous gentle movement. The outflow of water being drawn by city demand created suction on the pipe, which brought more water through the S-shaped channels of the basin, which would mix the water relatively evenly as it moved through the basin.

Work on the entire unit proceeded smoothly through 1921, despite a fire at the boiler house of the company building it out. The water board organized a series of roads to link the reservoirs to the filtration plant. They also built out a power plant for washing the sand used in the plant. On Feb. 6, 1922, the new filter plant began sending purified water into the network, finally completing the Nepaug project.

Reservoir filtration plant and aerator fountain, taken around 1955. Aerial view of the filtration plant and aerator (top left) in 1934; the current view looks nearly the same.

Almost a decade later, city officials visited the reservoir plant along with the newly formed Metropolitan District Commission to inspect the waterworks. When they arrived, the sand from the filter beds was undergoing the annual “bath”; it was washed in special machines to remove the black scum forming on the top layer. This layer, called the schmutzdecke (German for “dirty skin”), was essential for filtering bacteria, but it could degrade over time and slow down the water flow. Therefore, operators would scrape off the top few inches of sand and wash it in these mechanical machines to reuse them in rebuilding the filter beds. Next, they visited the aerator, which “was spouting geysers several feet high.”

Managing the filtration plant was Arthur Brosmith, who had been employed at the reservoir since 1916. He demonstrated to the officials how the water was tested daily in the lab, taking samples from tiny jets in the reservoirs themselves and studying them under microscope. Brosmith was superintendent of the Water Bureau of the Metropolitan District when he contracted a lung illness after inhaling chlorine gas in a manhole while on a tour of inspection during the 1936 flood. During the 1936 flood, Hartford and surrounding areas suffered major inundations. Brosmith was on tour to assess underground chambers, especially chlorination rooms that were widely used still in some facilities. Chlorine had leaked into the low area inside a manhole and he damaged his lungs while checking it out.

He retired for his health and left for Saranac Lake in the Adirondacks, where patients with tuberculosis and other illnesses often went for fresh air. He died there in 1941, a casualty of the water system he helped oversee.

Over time, the six reservoirs in the original system were cut down to four supply reservoirs. One became Batterson Park while Reservoir #1, the original supply body, was converted to generate power for the filtration plant. The other four became the reserve sources if the reservoirs at Nepaug and Barkhamsted were interrupted.

By the end of World War II, water from the Nepaug was carried to the filtration plant in West Hartford through two pipelines. Eight filter beds were expanded to include six more, covering 7.5 acres. A second storage basin was constructed as well. Chemical treatment before the war hadn’t been necessary, but chlorination was instituted as a wartime protection.

Water demands after the war into the 1950s greatly increased. The Metropolitan District looked to tap new sources of water, like the west branch of the Farmington River. The Hogback Dam was completed in Colebrook in 1955, the same year that Hurricanes Connie and Diane hit.

Beyond the added supply, the filtration plant saw innovations over the years too. In 1957, the MDC approved the use of fluoride in water. Studies had shown striking drops in childhood tooth decay and national health agencies officially endorsed the fluoridation movement. It also followed the trend of the day: science could solve social problems, whether it was the atom bomb, antibiotics, or chemicals in the water.

Geopolitical events also had an impact on the filtration plant. Engineers in 1922 had installed a turbine and generator that captured the energy of the water before it entered the city mains and powered the infrastructure and equipment, a sort of self-powering system. The small hydro generator over time though would have been inefficient by modern standards and require more expensive maintenance. The MDC retired it in 1971 when energy was cheap; power from Northeast Utilities was inexpensive and reliable and low-cost oil was plentiful.

The 1973 OPEC oil embargo and 1979 Iranian Revolution, however, caused energy prices to quadruple over the decade. Electricity prices, in turn, rose steeply since utilities generated power with oil or natural gas. President Jimmy Carter began promoting small-scale renewable energy, rehabilitation of existing equipment, and tax incentives for retrofitting. The second oil crisis had driven energy costs to record highs and Carter proclaimed: “We can promote use of small hydroelectric plants, powered by the flow of ordinary streams, without the need for big dams.” In response, the MDC began using the hydroelectric unit again, reaching back to a previous era. 170 years ago, steam engines began pumping Connecticut River water to a reservoir in Hartford. Modern improvements in public health brought chlorination for sanitation and later filtration of massive amounts of water coming from the Nepaug valley.

By the 1930s, the West Hartford reservoir system was a fully operational, scientifically tested maintained machine for the upkeep of suburban (and city) life. Public health and energy concerns ran in parallel with the burden of suburban growth.

Nearly 50 years later, As the MDC wrote in their commemorative book in 1955, “Tomorrow will also undoubtedly bring fresh supply problems.” Once each generation, it would seem from Hartford’s water supply history, new supply bases must be found.

Jeff Murray was born and raised in West Hartford and has been involved with the Noah Webster House & West Hartford Historical Society since 2011 when he was a high school student and won the Meyer Prize for his essay on local history. Jeff routinely volunteers as local history researcher uncovering information for numerous museum programs such as the West Hartford House Tour and West Hartford Hauntings. Jeff works as a data analyst at Pratt & Whitney.

Like what you see here? Click here to subscribe to We-Ha’s newsletter so you’ll always be in the know about what’s happening in West Hartford! Click the blue button below to become a supporter of We-Ha.com and our efforts to continue producing quality journalism.

Great piece, Jeff! Interesting and relevant as always. I look forward to your pieces all the time.

This is a very well written piece on the development of a public water supply system. Having worked in the drinking water industry in New York State for many years, there are many parallels to the development of public water systems in New York, primarily systems with an upland, gravity, source of supply, and the introduction of slow sand filtration and chlorination in the early 20th century were key developments in public health protection. As long as these systems are maintained, they should be able to provide many years of reliable service. Thanks for an enjoyable read.